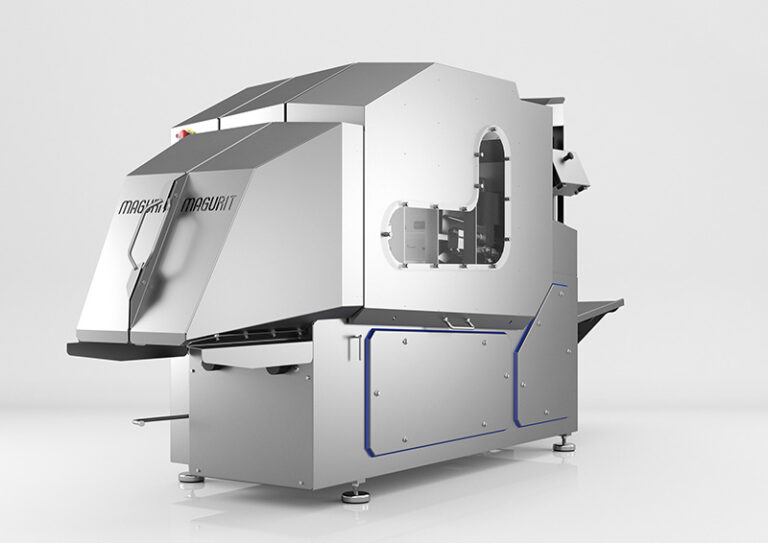

Food and pharmaceutical industries worldwide rely on Magurit freeze cutters for precise and safe cutting of frozen products. Known for setting benchmarks in quality and machine safety, Magurit Gefrierschneider GmbH, based near Cologne, Germany, excels in delivering cutting solutions that meet rigorous industry standards.

Cutting Edge Technology and Safety Standards

Magurit specializes in machines for slicing frozen raw materials, such as meat, fish, and fruit concentrates. The company’s expertise extends to pharmaceutical applications, including the cutting of frozen blood plasma used in medicines. With a rich history dating back to 1859 and a legacy of family ownership, Magurit stands out as a global leader in this niche market, boasting an impressive 80% export ratio.

Commitment to Machine Safety

In the realm of machine safety, Magurit demonstrates a blend of tradition and innovation. The company’s long-standing partnership with Schmersal highlights its commitment to both continuity and progress. The Protect Select OEM compact safety controller from Schmersal, used across Magurit’s series, exemplifies this approach. Designed for applications requiring up to five safety functions, it offers a user-friendly interface with preconfigured programs and adjustable parameters, eliminating the need for complex programming.

Custom Solutions for Enhanced Safety

Magurit’s use of Schmersal’s Protect Select OEM controllers underscores their strategy of employing customizable safety solutions. For over 25 years, Magurit has utilized bespoke safety modules, allowing for the activation of specific functions as needed. This streamlined approach simplifies operations and reduces costs compared to traditional relay modules. Additionally, the flexibility of the Protect Select system accommodates future updates, such as the addition of new safety functions.

Innovative Safety Sensors

To meet high hygiene standards, Magurit employs non-contact safety magnetic sensors concealed behind stainless steel covers. These sensors, paired with uncoded actuating magnets, prevent tampering and ensure reliable operation despite the strong vibrations inherent in freeze cutting. When conditions permit, coded magnets are used for added precision.

Hygienic Design and User Interface

The N programme from Schmersal addresses the stringent hygiene requirements of the food and pharmaceutical industries. Its operating elements are designed for easy cleaning and are free of areas where residues might accumulate. Magurit plans to transition to Schmersal’s new H series, which offers modular flexibility and compliance with the latest standards, including DIN EN ISO 14159 and EN 1672-2.

Looking Ahead

Magurit’s focus on safety, innovation, and hygiene underscores their dedication to advancing machine technology for the food and pharmaceutical sectors. By integrating state-of-the-art safety controllers and maintaining high hygiene standards, Magurit continues to lead in delivering safe, efficient, and reliable cutting solutions.