Aerospace manufacturing has long been at the forefront of innovation, particularly when it comes to creating lightweight, high-performance parts. The demand for materials that offer exceptional strength while keeping weight to a minimum is crucial in aircraft and spacecraft design. Carbon fiber composites and lightweight metals dominate the sector for their excellent strength-to-weight ratios, yet crafting these complex parts requires precision techniques and advanced technologies. Through methods like autoclave molding, multi-axis milling, and additive manufacturing, aerospace manufacturers are pushing the boundaries of what’s possible in lightweight design.

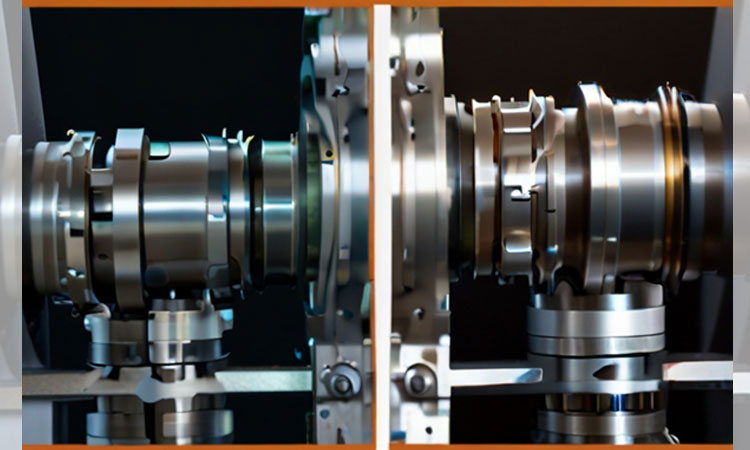

Multi-Axis Milling: Precision for Complex Geometries

One of the most powerful techniques used in aerospace manufacturing is multi-axis milling. Unlike traditional milling methods that use a single axis of rotation, multi-axis milling expands the process to include multiple rotational axes. This allows manufacturers to create parts with intricate geometries and complex shapes that would otherwise be difficult or impossible to produce. By enabling machining from different angles, multi-axis milling ensures the precise dimensional accuracy and smooth surface finish required in aerospace applications. The ability to optimize part designs for maximum strength-to-weight ratios makes this technique essential in meeting the rigorous standards of the aerospace industry, particularly in structural components where every ounce matters.

Electrical Discharge Machining (EDM) and Laser Cutting: Enhancing Detail and Precision

Electrical Discharge Machining (EDM) is another crucial technique that plays a significant role in the manufacturing of lightweight aerospace components. EDM allows for the creation of highly detailed parts with tight tolerances, which are particularly important for turbine blades and other high-stress aerospace components. This process uses electrical discharges to remove material, offering incredible precision without physically touching the workpiece. As a result, EDM is ideal for creating parts with intricate features and complex shapes, all while minimizing material waste — a key consideration in aerospace manufacturing’s drive for sustainability.

Laser cutting, on the other hand, is revolutionizing part fabrication with its ability to make high-speed, precise cuts. This method is particularly useful for producing parts with tight tolerances and intricate geometries that are essential in aerospace applications. Laser cutting generates minimal heat, preventing thermal distortion in sensitive materials while maintaining their integrity. Its speed and efficiency make it indispensable for the production of lightweight aerospace components, contributing to faster turnaround times and cost-effective manufacturing, all while ensuring superior part quality and aerodynamic efficiency.

Additive Manufacturing: Revolutionizing Lightweight Design

Additive manufacturing, or 3D printing, is emerging as one of the most transformative technologies in aerospace. This technique involves depositing material layer by layer, creating parts with minimal waste and highly optimized designs. Unlike traditional manufacturing methods that remove material from a larger block, additive manufacturing builds parts from the ground up, allowing for the creation of lightweight, complex shapes that would be impossible to produce through other means. By using materials such as titanium, aluminum, and even specialized polymers, additive manufacturing enables the aerospace industry to achieve designs that balance weight reduction with structural integrity, unlocking new possibilities for the next generation of aircraft and spacecraft.

Pushing the Boundaries of Aerospace Manufacturing

Through innovations like autoclave molding, multi-axis milling, electrical discharge machining, laser cutting, and additive manufacturing, the aerospace industry continues to redefine what is possible in lightweight design. These techniques not only enable manufacturers to meet stringent performance requirements but also drive sustainability by minimizing waste and optimizing material usage. As these technologies evolve, aerospace manufacturers are paving the way for high-performance, environmentally friendly solutions that promise to revolutionize the future of aviation and space exploration.

Image courtesy: Design by Freepik