Automation and robotics are rapidly transforming the aerospace and defense machining sectors, enhancing manufacturing processes to achieve new levels of efficiency, precision, and adaptability. From robotic machining cells to automated tool changers, these technologies are at the forefront of revolutionizing aerospace and defense manufacturing, enabling manufacturers to meet demanding industry standards.

Robotic Machining Cells: Revolutionizing Precision and Efficiency

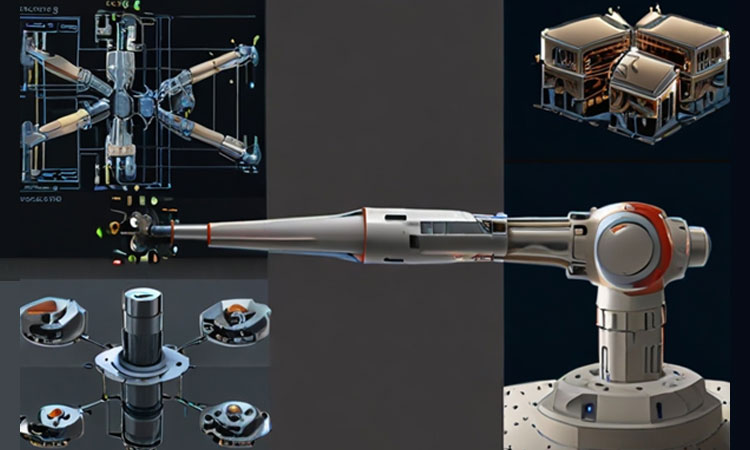

Robotic machining cells have emerged as a pivotal development in aerospace and defense machining. These cells combine robotic arms with Computer Numerical Control (CNC) machines, enabling the execution of intricate machining operations with exceptional speed and accuracy. Equipped with advanced sensors and vision systems, robotic cells ensure precise tool positioning and part manipulation, making them ideal for performing complex tasks. By automating repetitive operations, these cells not only enhance productivity but also significantly reduce cycle times and minimize human error. As a result, aerospace and defense manufacturers can achieve higher levels of consistency and reliability in their machining operations.

Automated Tool Changers: Maximizing Efficiency and Reducing Downtime

Automated tool changers are another critical innovation that optimizes machining processes in the aerospace and defense industries. These systems automate the process of switching between tools, eliminating the need for manual tool changes and reducing downtime between machining operations. By offering seamless transitions between different tools and processes, automated tool changers ensure that the right tool is available for each specific machining task, maximizing productivity and minimizing setup time. This capability is particularly valuable in aerospace and defense machining, where complex components often require multiple tool changes during production.

Adaptive Machining: Enhancing Precision Through Real-Time Adjustments

Adaptive machining represents the next step in optimizing aerospace and defense manufacturing. By utilizing real-time data and feedback, adaptive machining systems can dynamically adjust cutting parameters and tool paths to optimize machining efficiency and surface finish. These systems continuously monitor machining conditions and part geometry, enabling manufacturers to fine-tune tool engagement, feed rates, and cutting speeds as needed. This real-time adaptation ensures consistent results, even when working with varying materials and geometries. Adaptive machining not only enhances precision but also reduces machining time and tool wear, further improving operational efficiency.

Driving Innovation for Aerospace and Defense Manufacturing

The integration of automation and robotics into aerospace and defense machining has resulted in significant advancements in manufacturing. Robotic machining cells, automated tool changers, and adaptive machining processes are driving efficiency, flexibility, and precision to new heights. By reducing cycle times, improving accuracy, and minimizing human intervention, these technologies enable manufacturers to meet the stringent demands of the aerospace and defense industries with unmatched precision. As these technologies continue to evolve, they will play an increasingly vital role in shaping the future of aerospace and defense manufacturing, ensuring manufacturers remain competitive in an ever-evolving landscape.

Image courtesy: Design by Freepik